Jorge Cañada Jul 6, 2018 11:10 | Dear author, Thank you for submitting your proposal to this contest. I would like to remind you that you have less than ten days left to work on your proposal before the finalist selection phase begins. Good luck, Jorge |

Emil Jacob Jul 10, 2018 03:47 | Proposal contributor Dear Jorge, I updated the proposal. Please let me know if there is anything else you think I should add. Thanks, Emil |

Jorge Cañada Jul 11, 2018 09:01 | Dear Emil, Thank you for your updates. Just check that your proposal meets the "key issues" described in the contest information. Good luck, Jorge |

Christopher Fry Aug 17, 2018 07:37 | This proposal has some innovative design so I want to encourage the author to improve it by fixing the below flaws: The title says "Vertical axis ..." Value proposition says "CHEAPER" The smaller versions of this have potential. Batteries that can support intermittent sources of power like wind and solar are coming so we should not discount proposals such as this one for not supplying energy storage. The author is talented enough to find a way to integrate energy storage into these structures. Perhaps a "gravity battery" is appropriate given that the structure already provides "height". Perhaps there's surface area on these wind turbines to ALSO have solar panels to give us both wind and sun power from one structure. |

Emil Jacob Aug 20, 2018 12:23 | Proposal contributor Hi Christopher, Thank you for your feedback. I will correct to "vertical" - once I can edit. About the cost we plan to use the info from the following website: http://www.windustry.org/how_much_do_wind_turbines_cost A 2MW wind turbine is estimated between $3-4m installed. We plan to simulate power of 2MW from our model and estimate the costs including installation and see if it can be done under $3m. We also also simulate smaller ones that can fit on the buildings and estimate the cost.

About Solar we will include solar at the top and also in "blinds"

Thank you again for your feedback!!!!!!!!!!! Emil |

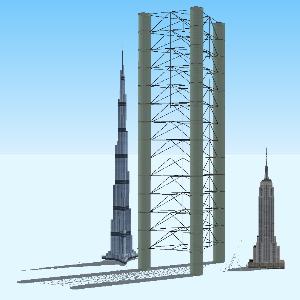

Emil Jacob Aug 27, 2018 01:55 | Proposal contributor Dear Judges, We are working on calculations in relation to a traditional 2MW wind turbine - estimated between $3-4m installed. http://www.windustry.org/how_much_do_wind_turbines_cost Our model will have a comparable height of 300 ft, and a diameter of 30 ft. From preliminary calculations of this scale we are showing significantly greater output than traditional 2MW wind turbine. In terms of costs the materials and construction of our model comes to about half of the equivalent horizontal axis windmill. Budget Estimates for Vertical Windmill with Height 300ft and Diameter 30ft concrete pole 300 ft tall - 1x1 ft -> 300 cubic feet per pole -- cost of concrete per cubic ft 4 dollars cost of concrete per pole $1200 dollars cost of concrete 6 poles 12000 dollars for 1800 cub feet of concrete https://www.concretenetwork.com/concrete-prices.html Cost of steel per cubic foot 160 http://www.pages.drexel.edu/~jpm55/AE390/A3/materialsparams.htm TRIPPLE the total concrete from 1800 to 5400 cubic feet of concrete ->$36,000 concrete Assume 10% of concrete to be steel - i.e. 540 cubic feet of steel 86,400 dollars Total of $122,400 for steel and concrete structure materials Cost of each rotating element (6ft tall) with blades, flaps, stabilizing wheels = $2,000 dollars Height of 300 feet fits maximum 50 rotating elements i.e. $100,000 Cost of a generator $300,000 Cost of netting or “blinds” coverage for safety $50,000 Total cost of materials $572,400 materials and equipment Dividing the 300 ft tall structure into 50 units - and assuming labor costs of $20k for every 6ft including installation of rotating element $1,000,000 labor costs Software and hardware $200,000 $1,772,400 TOTAL ----------------- We will be providing detailed calculations of energy produced. Thank you, Emil Jacob |

Emil Jacob Aug 27, 2018 07:20 | Proposal contributor We added a new element to the design which increases efficiency significantly. In the drawings below, image FIG. 5 shows vertical shutters 20 closed to capture the force of the wind; in FIG. 4 the shutters are open to reduce resistance. The shutters close and open around hinges. Stoppers marked with arrow 24 hold the shutters in place from the wind pressure direction shown by arrow 27. FIG. 5B shows the blade/wing of the windmill turned about 45 degrees from FIG 5 and with perpendicular wind force 27 on vertical shutters 20 - while wind force 30 from the turning blade also captured by vertical flaps. FIG. 5C is the same as 5B but without the vertical flaps showing the loss of efficiency when compared with 5B. This is the added improvement from the original submission.

|

Alex Sludds Aug 28, 2018 02:17 | Proposal contributor Hey everyone, I am a graduate student in Electrical Engineering at MIT who is working with Emil on this project.

Upper Limit on Energy Extraction from Air: There is an upper bound to the amount of energy that can be extracted from the air. This is defined by Betz’s law: https://en.wikipedia.org/wiki/Betz%27s_law Betz’s law says that for any wind flowing through an open space that no more than 59.3% of the kinetic energy of this wind can be extracted. Modern windmills fall short of this limit, often hitting 35% energy conversion efficiency.

Estimate for Energy Extracted By Vertical Windmill with Height 300ft and Diameter 30ft Assuming an efficiency of 35% and that air density is comparable with air close to sea level, we calculate the following graph using the equation: windpower = 1/2 *rho * A *V3 Where rho is the density of air in kilograms per cubic meter, A is the area that is swept by the turbine in square meters, and V is the velocity of the wind in meters per second. It is from this graph that we can see that there is the potential to harvest up to 10 megawatts of power from wind are speeds close to 35 meters per second. Since more turbines are rated for 2-3MW, this will mean that at speeds greater than at least 14 meters per second the turbine will be working at full capacity.

Estimate for Energy Extracted By Vertical Windmill with Height 6ft and Diameter 1ft Using a similar method as above we want to calculate how much power can be captured from a vertical windmill with a height of 6ft and a diameter of 1ft. From this method we find that it is possible for these structures to capture several kilowatts of power within favorable wind conditions. Estimate for Solar Energy Captured at the Vertical Windmill with Height 300ft and Diameter 30ft

Conventional solar panels have an power output of 15 watts per square foot. This means that for this windmill that if solar panels are placed on the roof that they could generate 10600 watts of power.

Estimate for Solar Energy Captured at the Vertical Windmill with Height 6ft and Diameter 1ft

Using a similar calculation to above we find that a smaller windmill with a 1ft diameter will generate about 11.7 Watts.

Budget Estimates for Vertical Windmill with Height 300ft and Diameter 30ft concrete pole 300 ft tall - 1x1 ft = 12000 dollars for 1800 cub feet of concrete https://www.concretenetwork.com/concrete-prices.html Cost of steel per cubic foot 160 http://www.pages.drexel.edu/~jpm55/AE390/A3/materialsparams.htm For the final design we can assume that 10% of the concrete will contain steel, this means that using the above costs per cubic foot that the cost of concrete and steel woul be 122,400 dollars

A 300 foot structure fits a maximum of 50 rotating elements such as blades and flaps. Assuming that in the worst case that each element costs $2000 then total cost for rotating elements is $100,000

A generator for a 300 foot structure will cost $300,000

A netting for covering the structure will cost at most $50,000

This means that our total cost of materials and equipment will be $572,400

Labor for installation is assumed to be $20k for every 6ft segment. This means that for a 300 foot structure there wil be $1 million in labor costs

Additional software and hardware for monitoring the system will likely cost $200,000

$1,772,400 TOTAL

New England Electrical Grid and the Duck Problem

The duck problem is a problem that arises whenever there is an excess of solar energy sources within an electrical grid. Since solar energy can only be generated during the day this means that in order to compensate for the lowered demand on the grid, power utilities have to shut down power stations to avoid overloading the grid. This image demonstrates the effect of the duck curve:

As more and more solar energy sources become attached to the grid, this becomes a bigger problem. It is for this reason that certain states have solar caps.

One benefit of the vertical axis windmill is that it can be used to offset solar energy's effect to the electrical grid. This can be done by storing wind energy throughout the day and then putting that stored energy back into the grid as the sun starts to set. In this way power plants no longer need to be shut down and turned on again, saving lots of energy and time.

|

Alex Sludds Aug 28, 2018 03:38 | Proposal contributor As a quick follow up to my earlier post, I want to add a few things and some concluding remarks. In conclusion, in the worst case the vertical axis windmill will perform slightly better than a traditional windmill, but my expectation is that this vertical axis design will make better use of the area around the windmill as well as fluid dynamic effects with the wind, thus being able to extract more than 35% of the power from the wind.

Because of this lower footprint there is much better potential for these windmills to be used in urban areas, where the power is needed. This means that in a city such as Boston many demand problems in the power grid such as the duck curve can be mitigated by installing 100-200 windmills with batteries. This mitigation of the duck curve is great for the environment as turning on and off traditional power plants such as coal is incredibly energy expensive. In addition, these new windmills will allow for the construction of more solar panels without burdening the electrical grid. Large coal fired power plants can produce ~800MW of power. This power plant would be able to power approximately 130,000 homes. With the installation of 250-300 windmills this power plants contribution can be completely offset and the power plant can be replaced by a renewable energy source. In addition, because of the low maintence costs associated with windmills because of their reliability as well as their lack of constant staff the cost of the electricity from windmills will be lower.

One final comment is about the batteries within the windmill. Batteries would be placed close to the ground for easy access and to stay close to the generator / connection to the power grid. The capacity of flow batteries would be ideal for this application. Flow batteries on average cost $0.97 per kilowatt. This means that for a battery which can store charge for 8 hours of use at 2MW the cost would be $15,520. This does not include the cost of installation.

|

Emil Jacob Sep 3, 2018 04:23 | Proposal contributor An added feature that brings further advantage to this model is the ability to store and control energy output. Cylindrical reservoir at the center in the image below is used for storing water 68 which is pushed up along the walls of the reservoir through outer enclosure 52. Underground there is a water storage tank 71 from where water is pushed upwards along area 51 between outer part 52 and cylindrical wall 66. Propeller 74 is turned by the water pressure from inside the cylindrical wall and turning the generator 76. Given the height of 300' and the diameter of about 10' the force of the water pressing against the propeller 74 produces a significant amount of power. Having the water-battery has many other advantages, including the ability to control the power output into the the grid. In addition this feature is more cost efficient than battery technology.

This model can be incorporated into new construction and provides valuable economies of scale. In other words when a high rise building is being built the additional cost for the concrete and steel required is lower than when the windmill is being built independently from a new building.

CONCLUSION: We believe that the combination of the power storage and the design of the wind blades for maximum power capture via horizontal and vertical dynamic flappers makes this windmill model an essential tool for providing cheap and clean energy for the future.

|

Phan Manh Jun 15, 2020 06:42 | Great |