Pitch

The project explores how waste management in poultry and piggery farms can reduce emissions while ensuring clean energy to the farms.

Description

Summary

Poultry and piggery farming have emerged as one of the most profitable, flourishing and promising agribusiness enterprises in Uganda. They contribute significantly to both the national and rural economies through job creation for unemployed people and poverty reduction as their maturity harvest periods are short. Overall, the annual average growth rates in poultry and piggery production are 3.6 and 3.1 percent respectively from 2000 to 2015. Uganda is estimated to have between 40 and 50 million chickens. The proposed project explores how waste management in poultry and piggery farms contribute to emissions reduction, while ensuring clean energy (biogas energy) to the farms as well as social and environmental benefits for the poor. As the number of birds and pigs increase, poultry and piggery farmers in Uganda face two main challenges: (1) the large amount of animal waste on their farms- with approximately 5500 million tones generated daily by poultry and piggery enterprises combined; (2) the high cost of of using either diesel or wood fuel based backups whenever the unreliable grid electricity fails.

Therefore, traditional poultry and piggery farm management practices cause emission in two ways: emissions of the generated waste which is approximately 2.5 million tons of greenhouse gases from the 5500 million tons of waste, and emissions from use of either firewood or diesel powered captive generators as a source of heating. However, this waste could offer multiple social and economic benefits to the farms along with potential mitigation benefits, if it were converted into energy and it offers a great business opportunity for such farms with readily available inputs for biogas based electricity generation and promote green growth in these agribusiness enterprises.

Is this proposal for a practice or a project?

Project

What actions do you propose?

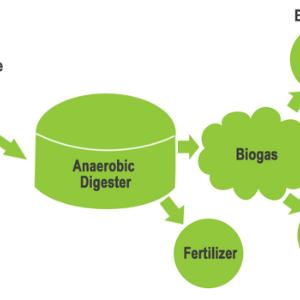

This project aims at improving the productivity of the poultry and piggery sub-sectors and at promoting clean energy use in Uganda. This will be through two main approaches: (1) Improving farm productivity through training and capacity building on farm management, disease and biosecurity management; (2) Promoting clean energy use through substituting biogas for wood fuel, diesel generated energy and hydroelectric power on smallholder farms. The project will utilize poultry and piggery waste to establish clean biogas energy technology in 30 farms, i.e., 20 poultry farms and 10 piggery farms. The poultry and piggery owners will be trained in developing their own technical expertise in building, operating and maintaining small-scale biogas energy plants. The project will also help farmers expand their farm capacities through better disease and biosecurity management and creating linkages for maximizing the revenue potential, particularly through sales of the slurry, a by-product of biogas production process or using it as fertilizer in their crop enterprises.

The biogas technology to be used in the project is fixed dome biogas digester design with a feeding point, a gas storage chamber and bioslurry exit channel. The digesters will be fed once a day with a fixed amount of organic animal waste mixed with appropriate amounts of water. This will improve farm waste management while producing biogas that will be used to run a generator to produce electricity at farm. Fixed dome digesters will be constructed below the ground using clay bricks and cement on circular concrete bases with their walls curving inwards to form domes. Biogas will collect in the dome. The neck of the dome will have a removable cover, which is sealed with wet clay and water. Whenever needed, the covers will be removed to conduct maintenance inside the digesters. The digesters will be plastered inside and outside with waterproof cement and a special gas-proof sealant to prevent any gas leakage. The digesters will have a feedstock mixing unit built about 50 cm above the ground, thus making digester feeding less labor intensive. As biogas is produced, the pressure rises inside the digesters, thereby pressing the bioslurry through the outlet channel to the expansion chambers.

We propose to this the fixed dome biogas plants because they have no moving parts on a fixed-dome digester, have a simple process mechanism and have a long lifespan of more than 25 years. Fixed dome digesters also maintain stable temperatures within the digester with no day or night temperature fluctuation, in addition to the low cost of maintenance compared to other biogas technologies. The downsides of the fixed dome digester design include a high investment cost, the need for building technical skills, and operational challenges of fluctuations in gas pressures. The project will use highly skilled personnel in construction to ensure the plants are gas tight and also in addition, use a special sealant to make the domes gas tight. However, the construction work of the fixed dome plants will be closely supervised by the experienced biogas technicians on our team.

Who will take these actions?

Geoffery Sempiri (Project Author) Holds a Bsc in Food Science and Technology from Makerere University and a Masters of Science in Food Technology of University of Ghent, Belgium. Geoffery is the head of the Science & Technology Infrastructure Development Unit at Uganda National Council for Science and Technology. He also teaches courses in Sanitation and Waste management, and Principles of Chemical processes at Bugema University, Luweero Campus. Geoffery has extensive experience in grants management and Science, Technology and Innovation infrastructure development. Geoffery will be the project coordinator.

Joel Tumwebaze has a BSc in Food Science and Technology from Makerere University and a Master of Science degree in Food and Nutrition Sciences from Tuskegee University. Currently Joel is a Ph.D. candidate of Nutrition Science at Auburn University. He has an extensive field and community mobilization experience he has gained working on community nutrition development projects in Uganda, Nicaragua and Tanzania. He will be responsible for community mobilization and outreach.

David Nganwa has a Master’s in Public Health from Makerere University and a Doctorate in Veterinary medicine from the University of Alabama at Birmingham. Currently David is an Associate Professor in the College of Veterinary medicine at Tuskegee University, USA. He has a broad background in epidemiology, risk analysis, public health and biomedical sciences. He specifically studies complex sets of hosts, environment, and agent factors as they interact to affect health and diseases of a given population and will be responsible for implementing the Animal Diseases and Biosecurity Management Component of the proposal.

Dr Joseph Kyambadde, PhD, Department of Biochemistry & Sports Science, College of Natural Sciences, Makerere University, Kampala. His research focuses on Agro-Waste Management and Biogas Technologies. He will be the lead on the biogas component of the proposal.

Poultry and Piggery Farm owners will provide the farmers on which the project will be implemented.

Where will these actions be taken?

Thirty biogas plants will be established in 30 smallholder farms (10 piggery farms and 20 poultry farms) in the village farming communities of Wakiso district in Uganda. Upon its success, the model will be adapted to other farming communities across the country.

In addition, specify the country or countries where these actions will be taken.

Uganda

Country 2

No country selected

Country 3

No country selected

Country 4

No country selected

Country 5

No country selected

Impact/Benefits

What impact will these actions have on greenhouse gas emissions and/or adapting to climate change?

Approximately, 2.5 million tons of greenhouse gases are generated from the 5500 million tons of waste and emissions from the use of either firewood or diesel powered captive generators as a source of heating. However, this waste could offer multiple social and economic benefits to the farms along with potential mitigation benefits, if it were converted into energy. It also offers a great business opportunity for such farms with readily available inputs for biogas based electricity generation and promotes green growth in these agribusiness enterprises.

What are other key benefits?

Direct economic benefits through (i) reduced poultry and piggery farm expenditure on hydroelectricity and diesel through use of the cheaper biogas instead; (ii) sale of the previously highly polluting poultry and piggery waste to be turned into fuel and fertilizer

Improved human and animal health. This will be through better hygiene conditions at the smallholder farms and increased biosecurity (protection from harmful disease and biological agents). Animal refuse left in the open acts as manure that leads to overgrowth of bushes that act as breeding sites for mosquitoes, beetles and tsetse flies. More to that, in its 2015 climate policy Uganda recognizes that rising temperatures are expanding the geographical distribution of disease vectors like mosquitoes to include higher altitudes, which intensifies the malaria pandemic. It is therefore, a climate change priority for the Uganda’s Ministry of Water and Environment to improve health by reducing the spread of diseases in the wake of climate change.

Increased nutrition security: The digested material (slurry) from the biogas plant can be used as fertilizer on crop farms to support other crop farming based income generating enterprises

Reduced pressure on the over-stretched electricity grid and forests.

Biogas will support food value addition through drying produce such as mangoes, pineapples and vegetables. This will not only ensure food availability beyond food production months but also create small scale food processing ventures ensuring both food security and job creation as envisioned in 2040 National development plan.

In addressing climate change, the Ugandan Ministry of Water and Environment takes into consideration protection for the vulnerable groups of which women and children are part. In Uganda, like many other developing countries, collecting wood fuel is primarily the role of women and children. Biogas production on farms will not only save vulnerable populations from the tedious risky work of collecting firewood but free time for education attainment and other developmental activities.

The team proposes use of biogas for heating, food preparation and lighting within farm human homes. In Uganda, more than 70% of the population relies on wood fuel for cooking and heating in homes which usually happens in enclosed spaces with open fires. This poses a risk for indoor air pollution to household members a disadvantage that can be overcome by use of biogas. As fires are left to burn overnight for warmth and light, they have been known to burn animal farms and families yet biogas can easily be turned off with a switch.

Enhanced farmer awareness of environmental protection. This will act as a knowledge base and motivation of the farm owners to invest in sustainable and efficient energy use.

Costs/Challenges

What are the proposal’s projected costs?

Project preparation (planning meetings, mobilizations) 2734.1 USD

Project awareness (Sensitization workshops, experience sharing) 10936.4 USD

Equipment modifications, materials (construction of bio-digesters, generators, piping and wiring) 136705 USD

Biogas Technology Training (capacity building, maintenance, sustainability) 27341 USD

Farm, disease and biosecurity training for the 30 farm owners and employees 27341 USD

Project M&E (Participatory monitoring and Evaluation) 27341 USD

Dissemination of Reports (Preparation, production) 13670.5 USD

Grand Total 246069 USD

This budget is for three years

Challenges and solutions

Generally, there is ignorance about biogas as an energy source among the very people who would benefit from it. This will be overcome through sensitization the public on the advantages of changing to biogas and demonstrate through hands on training that biogas technologies are safe and secure.

The proposed Fixed dome plants are not easy to build as they require highly skilled and experienced masonry technicians, otherwise, cracks will develop and the gas will leak. We propose to use highly skilled personnel in construction to ensure the plants are gas tight and also in addition, use a special sealant to make the domes gas tight. Also the construction work of the fixed dome plants will be closely supervised by the experienced biogas technicians on our team.

The challenge of limited mixing between chicken manure and water a hindrance that may lead to non-generation or less quality gas production. This is evident given the production of biogas requires a mix of both water and manure yet chicken manure is low in water compared to pig or cow manure. This will be solved by mixing chicken manure with pig manure and water in a mixing chamber and possibly connecting a human urinal to the biodigester. To reduce the need for fresh water, the slurry separation technique to recover and recycle water from the digester to produce a more easily drier handle-able bio-fertilizer wii be used.

In situations of increased need for biogas, farms may encounter less manure production but the project team will encourage farm owners to travel to neighboring farms and work out deals of mutual benefit between farms.

There is a perception that biogas is unhygienic given that manure is smelly and bacteria infested. This is more perceived especially during preparing the slurry feed for the digester and during cooking. The team will explain hygienic handling practices during preparation of the slurry and that biogas formation is a chemical irreversible change and that the gas is free from bacteria.

Lastly, for additional safety and efficiency the team will emphasize that the gas equipment be carefully and regularly cleaned to prevent corrosion and leaks. The reactors should also be emptied once every 5 to 10 years. These operational procedures require no skilled operator if the households are trained to understand the system

Timeline

In the short term, the team projects increased monetary savings by not relying on hydroelectricity and from the sale of digestate. Biogas plants will serve as disposal points for waste and sewage and directly contribute to better hygienic situations for individual users. There will also be improved health outcomes arising from the use of clean energy and from improved sanitation leading to reduced medical costs. When the slurry is used as a fertilizer in crop fields, there will be an increase in crop production leading to an increased output level of crops keeping pace with increasing population. The substitution of commercial fertilizers with slurry from biogas production will reduce impacts of balance of payments by decreasing reliance on the importation of chemical fertilizers.

In a medium term, households will see an increased value for money through investing in other necessities like education, business ventures and improved living conditions consequently leading to increased life expectancy. Reduced deforestation resulting from replacing conventional fuels like kerosene or firewood, will allow for increased carbon sequestration. At present, there is increased rural urban migration but decentralized biogas units, on the regional level, may improve the distribution of income amongst income brackets and reduce regional disparities. This will ultimately enhance the attractiveness of rural life.

After 50 years of biogas use, considering that biogas plants are adopted on a regional level, decreased deforestation will lead to increased value of saved forests as a recreation center and reduction in soil erosion hence increasing the value of agricultural land. At the local level, biogas projects will directly offer permanent employment for the operation personnel and or indirectly result in contracts with local and regional companies for the service and maintenance of a plant including the gas-burners in the households.

About the author(s)

Geoffery Sempiri Holds a Bsc in Food Science and Technology from Makerere University and a Masters of Science in Food Technology of University of Ghent, Belgium. Geoffery is the current head of the Science & Technology Infrastructure Development Unit at Uganda National Council for Science and Technology. He also teaches courses in Sanitation and Waste management, and Principles of Chemical processes at Bugema University, Luweero. Geoffery has extensive experience in grants management and Science, Technology and Innovation infrastructure development. Geoffery will be the project coordinator.

Joel Tumwebaze has a BSc in Food Science and Technology from Makerere University and a Master of Science degree in Food and Nutrition Sciences from Tuskegee University. Currently Joel is a Ph.D. candidate of Nutrition Science at Auburn University. He has an extensive field and community mobilization experience he has gained working on community nutrition development projects in Uganda, Nicaragua and Tanzania. He will be responsible for community mobilization and outreach.

David Nganwa has a Master’s in Public Health from Makerere University and a Doctorate in Veterinary medicine from the University of Alabama at Birmingham. Currently David is an Associate Professor in the College of Veterinary medicine at Tuskegee University, USA. He has a broad background in epidemiology, risk analysis, public health and biomedical sciences. He specifically studies complex sets of hosts, environment, and agent factors as they interact to affect health and diseases of a given population and will be responsible for implementing the Animal Diseases and Biosecurity Management Component of the proposal.

Joseph Kyambadde, PhD, Department of Biochemistry & Sports Science, College of Natural Sciences, Makerere University, Kampala. His research focuses on Agro-Waste Management and Biogas Technologies. He will be the lead on the biogas component of the proposal.

Related Proposals

References

Hurst C and Barnett A. (1990) The Energy Dimension-A Practical Bioenergy Systems Report: Innovations in Biogas Systems and Technology (1984) Bioenergy System and Technology Project of the USAID

Guide to Energy in Rural Development Programmes. Intermediate Technology Publications

Waste as a Renewable Energy Source>: Available at:http://www.alternative-energy-news.info/waste-renewable-energy-source

Werner U., Hees N and Stohr-Grabowski U (1989) Biogas Plant in Animal Husbandry: A Practical Guide. Friedr. Vieweg & Sohn Braunschweig/Wiesbaden

FAO/CMS (1996) Biogas Technology: A Training Manual For Extension. Published by Food andAgriculture Organization of the United Nations.http://www.energycentral.com/c/gn/renewable-energy-food-wastes

A guidebook to the Green Economy. Available at: https://sustainabledevelopment.un.org/content/documents/GE%20Guidebook.pdf

Hasan and Mahmudul (2017) Feasibility Study of Biogas Energy in Bangladesh. Electrical and Electronic Engineering.

Bansal V., Tumwesige V., Smith J.U., (2016). Water for small-scale biogas digesters in sub-Saharan Africa. Global Change Biology Bioenergy, 9, 339–357.

African Biogas Partneship Program (ABPP) (2016) Biogas digesters installation in sub-Saharan Africa. Available online at: http://www.snv.org/project/africa-biogas-partnership-programmeabpp (accessed October, 2017).

Achinas S., Achinas V., Euverink G. J. W (2017): A Technological Overview of Biogas Production from Biowaste. Engineering, 3, 299–307.

Grace MaaLaje Ofori (2016) Master Thesis: Waste to Energy: an alternate energy source for Ghana. Available at: http://lup.lub.lu.se/luur/download?func=downloadFile&recordOId=8881431&fileOId=8883951

Jönsson H., Stintzing A.R., Vinnerås B. and Salomon, E., (2004). Guidelines on the use of urine and faeces in crop production. EcoSanRes Programme.

The Republic of Uganda Ministry of Water and Environment, (2015). Uganda National Climate Change Policy: Transformation through climate change mitigation and adaptation.

Wawa A.I (2012). The challenges of promoting and adopting biogas technology as alternative energy source in semi-arid areas of Tanzania: The case of Kongwa and Bahi districts of Dodoma region (Doctoral dissertation, The Open University Of Tanzania).