Off-grid Demo Tiny Home & Shop with Rain+Snow Cisterns for Food Crop Terracing by Tiny Home Off-grid

Pitch

Off-grid tiny home demo w/biodiesel from septic tank effluent, all-electric, std constr to code, 14x20ft 2-story+grnhs, H2O w/cistern, 3kw.

Description

Summary

To Demonstrate Off-grid, Net-zero Methods for Existing Homes, then, Develop Windmills for Shop Power, and finally Prototype a Biodiesel from Sewage Effluent System to be used for heating or vehicles.

To have an off-grid wood frame pass code is one problem builders face, add in a cool climate it's a challenge, having the biodiesel is very novel and closes a missing need for truly sustainable home-farm-ranch scale living.

It's rather fast to build being small, the expectation is to have some nice windmills within a year of breaking ground, then ready for mini-grid reliable.

- The property was chosen for small windmill development to leverage Dabiri Arrays that extract 10-times more power per hectare than the 1Mwh, 120m tall HAWTs using verticals.

- Success with these supports mini-grid needs in capacity, with designs specific for these windmills ready to R&D.

- This is an outgrowth of the shop along with the tiny home demo, the developed windmills powering future shop needs, a shoestring bootstrap budget.

- Plans are ready for an architect to work into drawings for permitting.

- Hemp-mortar used where possible: CO2 absorber over its lifetime.

- Hemp-mortar creates an independent thermal-mass for heat any direction that allows moisture to transfer; fireproof on exterior walls.

- Providing a biodiesel for this project will open interest in scaling up, biodiesel for vehicles needs handling methanol so best for ranch & farm, in town trade your raw for biodiesel w/o the glycerol.

The place is a wind-savvy town, they live with it and can appreciate getting more power from it than the wind-farms visible from town that don't help their winter heating bills that for most is all-electric plus wood from rapidly dwindling forests.

With a goal of spreading the technology for leveraging wind power to propose a test plot to replace their grid wattage with wind-solar both good there, this as a town that serves the western states with similar needs and alternative resources.

What actions do you propose?

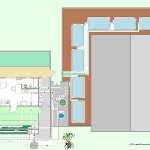

That is the tiny home demo plan with an existing field garage to be a shop-lab-studio that will be the main rain source with cisterns buried to also berm the building from the strong, cold winds.

The basic tenet of doing this is to own the generation & storage equipment for power, and the ability to have a water system based on rainfall.

By owning it's an asset, a capital expense amortized over 20-years & paid by the month so end-of-year you gain equity on the asset & for small business depreciate the value to salvage on taxes.

Simply, it's either black or red on the profit-loss sheet. If you buy power by-the-watt and for simplicity pay the same per watt as buying the equipment, it's an expense from cash on usage, so comes directly from profits as a cost-of-operation.

As an asset it contributes to profits balanced by liabilities & equity, it's cost is interest & fees not wattage so as a small restaurant with a zillion refer's & freezers & all that money spent supports those & more, when closed that excess capacity can be used elsewhere by plan to supplement revenue, freeze more ice for tomorrow's hot day and all and it doesn't cost more.

Scaled to a town everything becomes locally cheaper, the money that used to go out of town to big pockets overseas to avoid taxes stays in town, I'll get back to this important part of the demo in a semi-rural area.

The core of any home is the water system, power is easy now to generate & store, 30kwh of battery is only $11k enough to power a large home so that capacity picked for system capacity for the demo.

Heating degree days are 6,600/yr, a cold broad valley with prevailing winds only grows hay and alfalfa; seasonal drought 3.5-4.5 mo/yr, less than 1/2" rain/mo 6-mo/year but great wind power & good winter solar on an open lot.

Lot has no sewer nor a well, 16"/yr in rain-snow, 2/5th snow; high evaporation rate from the drying & direct sun if shelted, rain-shadow winds; rural lot very close to town, 1-acre with a field 3-door garage no home.

The garage roof is perfect for rain, to keep it warm a berm system is put in with the cisterns on the north & west side 6ft/2m high, this keep the shop cozy using far less heat, reduces wind gust area to the walls & provides a stepped terracing for a better look.

This allows gravity flow from the cisterns to the main water inlet where a pressurized tank is used. The filtration system will be pre-built by Earthships to the spec, water from this system typically is more pure than any tap in an offices, and no chlorine so you notice dining out most water is bleh!

The filter board has several types and there is a separate drinking water tap in bathroom & kitchen, piped to the shop to keep it all in one place to service; a key issue always is that these pass code.

Sewage processing uses Earthship's quasi-aquaponics to clean greywater to flush the toilet and that's a second use to the main greenhouse plants, they are there to purify water not for food in general as you want roots densley packed to absorb nutrients.

The kitchen sink goes into the septic tank with the toilet, too much grease & food scraps for the greywater system that is divided into a peat filter, a main section and the treated water section.

To pass code a leach field is installed, and for Earthships use for an outdoor botanical cell to grow plants around the home had an overflow to the leach field, rarely if ever needed.

Piping is installed for a home biodiesel system using the septic tank effluent to grow algae so uses the same concepts as my previous contest entry on wastewater systems at the home scale with the same end goals of later on being able to purify & recycle all water this way.

The cost of R&D on that way too high what is presented here is mainly gained by me using my VA Loan Eligibility to get it built, from there the rest may follow with people able to see the metrics and know it passes code.

Winning the contest would allow me to build this.

To protect the core from wind a 4ft hemp-mortar wall holds glazings at 45-degrees to the wind as gusts over 35-knots are common, this encloses 14ft of soil on two sides with the glass allowing sun into it most of the year.

Thermal collection & storage are a main piece missing from modern architecture, how to add them in to existing homes is a problem and to deal with this a crawl space thermal stack is installed that can work for any home.

The key is to use cement blocks on their sides to support the water bladder tank used as thermal-mass for the ducting it provides, then a manifold to the roof collector and duct system of the home, has an electric backup heater for code.

The roof collector are the solar panels mounted like glazings and weathertight over a thin, airtight box ducted to the crawl space for heating or cooling at night. A hot-water heater goes along the toe of the panels, these stacked on the greenhouse at the correct angle give full headroom on the second floor, bonus view.

So far this is functionally designed, doing that I like the sloping glass and low wall, the decks are 6ft wide and the battery box on the east landing near the PVs to save on costs wiring to the main panel.

Originally the foundation design was a concrete footing pad with corners & "posts" on 4ft centers between filled in by hemp-mortar, from a recent article it's possible now to use steel & anchors in hemp-mortar with a touch of cement alone, much easier.

The point is hemp-mortar removes CO2 over the lifetime of the wall and provides insulation from heat-loss via conduction to the foundation, fungus can't grow, it's alkali so termites & insects not a problem; also in moist areas, it transpires moisture slowly so crawl spaces can dry out in season.

Next is wall insulation.

From heat-transfer studies it's obvious the best place for insulation is outside the sheathing, wall batting hardly matters by contrast. You can see the difference in color this a 6.4-hr model run, 20C/0C the delta-temp with a standard wall doing badly.

Then modeling hemp-mortar showed it was better than foam insulation board, 4:1 vs 3:1 better and analyzing that from having thermal-mass to slow the heat flow down that much with so little insulation.

Then I modeled a wall with only outside insulation and it was still about twice as good, sold, the tiny home gets outside hemp-mortar and no inside batting. Instead the sheathing is nice plywood pre-finished with shelving anywhere I want between pre-finished studs, zero sheetrock.

This saves a ton of time as well as materials and the wall is more thermally efficient, it's a big ticket item to get approved to build because it means a siding job can reduce heat-loss to the average home to 1/3 even 1/4th what it is and not touch the interior for the mid price of a siding job using insulation board or hemp-mortar, adding for cabins the hemp-mortar is fireproof.

Those are the key integrations of Earthship principles and methods to a demo of how to apply them to existing homes, if I can move it that validates them to other architects & builders to have metrics to design from, a big part of the demo is data-loggers to create a library to use from them.

For power a contribution to windmills I'll be making are based upon Prof. John Dabiri's work at Caltech finding that small 10m high vertical-axis wind turbines, VAWTs, can produce 10-times more power per hectare than the 120m tall 1.5Mwh giants !!!

That got my attention to design specific rather DIY style VAWTs to leverage his work of 2kwh a unit these are paired and placed in an array on a hill, it takes 300 pairs to equal 1Mwh and you can't see them from a mile away, don't kill birds, are quieter, startup is at a lower speed & shut-down at higher.

For a small town there's a big list of pluses the main one owning the generating equipment is an asset to the town. With the shop on a perfect place to test windmills an intention is to put them out as plans, kits & pre-assembled along with the knowledge base of people to create mini-grids from existing substations for distribution and go off-grid as a town with base load reliable power using storage as the formerly missing piece to do that.

That's what building the demo is all about, infusing Earthship principles into housing, add sewage effluent fed algae-to-biodiesel at home-farm-ranch scale, and develop DIY windmills to support Dabiri Arrays to use for small town mini-grids.

Who will take these actions?

High Level Advisors:

Construction Related; Local Services - Titles; Ellensburg, WA:

Design sketches of details are being done almost daily to put final drawings out for permitting quickly, builder copies & all from the architect. This is a home-builder job using a licensed contractor-builder to bring in a plumber, electrician & excavator that want to refine as best we can the methods.

The positions comprising the team for construction to be filled locally:

Having the shop & tiny home demo signed off to live in is the primary goal, as stated the metrics will be logged & published on the website along with a real-time page for all research, wind & solar.

To create revenue as soon as the shop area is done for 3D-printing a product line of drone propellers is ready to go & easy to be a supplier into volume production at nearby industrial lots.

As a kitemaker & partner in a brick-n-mortar shop where we made kites for wholesale after studying sailboat design for decades, it was a freedom to experiment and have it flying in 2-3 hours from sketch to sky.

With that in mind the drone market is giant, my props will do fine to finance the final piece missing from Earthships, to use sewage effluent to grow algae for biodiesel in photo-bioreactors for home-farm-ranch scale.

With a small wastewater treatment utility in Oklahoma willing to help do the biology & certification, we were after a certified drinking water system, they liked that the units are semi-portable for farm remediation of spills that much.

That now is 9-years of serious research starting in Phoenix, AZ, having leading edge algae & solar labs, DOD-DARPA use them plus ASU's libraries and consulted with local treatment plant mgr's & tech's on how valid the idea would be.

Where will these actions be taken?

The location is the eastern Cascade Range, open land, high evaporation rate, cold semi-desert, latitude 45N, 15"/38cm rain & snow a year, 2/5ths snow, very strong wind resource. No crops this area, mainly hay, few operations left at modern land prices from very low rain during the growing season.

The principles apply globally to any structure any material. While the sewage effluent algae-to-biodiesel is a somewhat high-tech each unit is rather inexpensive, harvesting now can be done by EMF, using frequency to bust apart cells walls & release the oil cheaply at low power.

Thus, once a standard society shifts to making their own biodiesel like everyone owns a washer-dryer, it's part of the home-farm-ranch & so the Bell Curve of global society doesn't need a fossil transportation fuel.

In the USA about 6L/1.6gal a day per person is used for all types of transportation fuels, if scaled to sewage treatment plants it produces about 7.5L/2gal a day per person on a city system, much of the biofuel will be used for heating, with proper appliances and I suggest using low-power plasmas to deal with soot at the burner.

This can solve much of the woodcutting for fuel by using any compost, sewage, anything to make a liquor or tea from to feed algae with before biodigestion for the methane of what's left of those nutrients that way and much of the organic fibers and all are left for soils if not digested.

With a stone wall that means adding a hemp-mortar stucco 2cm thick to the exterior and the results are amazing on how much warmer it stays and hours longer on the same heat source. Doing this the condensation is greatly reduced because the inner faces of the stones stay at room temperature.

These are examples of the many ways to apply what the "demo" means that apply globally to the situation of needing to run all the IC-engines on a biofuel from a home that needs little and provides a modern lifestyle with far less negative impacts.

Then, growing food crops using terracing fits needs.

How much will emissions be reduced or sequestered vs. business as usual levels?

For the USA transportation fuels a city like Phoenix, AZ, makes 10M-gal/day in wastewater effluent, 20,750-tons of nutrients to feed the algae with per day if one paid for it at $400/ton it's value is $8.33M/day.

That produces about 3M-gal/day of biodiesel from sewage effluent and the USA burns 6L/1.6gal per day per person, this method can supply 7.5L/2-gal per person a day if done to scale. A dairy can use the washdown from a barn to make biodiesel to fuel the whole operation & recycle the water.

Then a hangup on alt power are windmills, they vary voltage & current so require storage for a regulated power supply from them, with the Dabiri Arrays this maps well to smaller, DIY windmills for mini-grids to 5Mwh for a small town 1-Mwh to 5-Mwh capacity of the wind portion.

Growing food crops on little rainfall in a cold windy place is meaningful to food security.

Taken together the reductions in emissions for society will be huge, transportation, home HVAC & agriculture on biodiesel.

What are other key benefits?

A main idea is that the home becomes the refugia, society then a place to interact from the personal inspiration to act not a demand to profit others.

Similar to the philosophy of art, using each material for its best use with the fitting method to enhance living as one can from the personal view of values.

These really are what drives "sustainable", careful looks at simple things which compound their effects over time, not to ignore it all for the gem peeking out of the soil, to farm the soil as the need.

This is a cross-section of the terrracing to be used for the berm against the garage based on the Inca method valid for 45° slopes, their savvy notable in hydrology, hydrostatic pressure in soils & dealing with it for 200cm/80" of rain a year.

That side gets full storm winds & rain with the choice of rocks it drains that without wetting the soil over the cisterns more, this will water the shady zone deeper into the loess.

A wind fence design tested in Reno can allow growing crops ...

What are the proposal’s costs?

As a path to revenue for TheSustainableStartup, a drone propeller design is ready for mfg to then do the next step with small windmills designed for mini-grids, to take small towns off the grid and use alt power instead including 1-5Mwh in battery-inverter storage arrays.

Prof. John Dabiri, Caltech, found small windmills paired can generate 10-times more power than the giant 120m tall ones. This DIY 1.5-2kw design can be paired to take advantage of his findings.

This is the path to global use of the principles to where towns are installing them from small shops, it takes about 300-pairs to produce 1-Mwh of wind power to add into solar arrays with regulated voltage & phase to existing substations.

Entering carbon figures in the Impact tool the total was 23,380-Gt, the whole idea has been to have principles apply anywhere for any budget to switch away from dependent living to food security & needs based housing.

The essential differences is using thermal heat-transfer as a guide not convention, to spot where the standard methods can be improved and to scale all must pass building codes, that's a big issue for existing homes if it costs too much it won't happen.

The mini-grid windmills finish the scope of innovation presented, being so useful to rural town needs used with large-scale storage now available in 380vdc systems for the 1-5 Mwh range, this is only for the windmill part.

Current design work shows the "towers" can be lampposts 8-12ft tall and the windmills only 4-ft in diameter the pairing take little space and can't be seen from 1km away, vertical-axis don't kill birds, are quiet and usually startup earlier, the current work has windmills that won't need to be shut down in storms.

Effort is being made to cut carbon, using hempcrete in the foundations & as the exterior insulation for garage & tiny home showing it's 4-times better than a standard wall in heat-transfer modeling.

There are many high-carbon items used, so this is a try at blending them well, and scale.

Time line

The timeline for remodeling the garage with the water & power part of that then the tiny home demo is 6-months to give time to figure out things. Excavations & thermal-mass soil insulation will add time & a recent thought is pouring footings on grade and build up to reduce the excavation work.

The enclosed porch now is a dedicated fresh food & sprouting area that will be plumbed in to work tables against the outer walls to hold trays, supplies is shelving under with the inner part for growing, insulated soils and separate from the greenhouse which is specific to greywater processing so not good for food plants there.

With the Moray pits and full land water system it's a year-round farming system intended to prove dryland techniques where well-water or irrigation are all that exists so that's at-risk for society as we watch snowpack lessen in the western states, the prediction is for 1/2 today's so yearly precipitation drops from 15" to 12" if rain stays constant.

Sales & revenue from props can be enough to speed up the terracing, it requires casting the custom tiles from hempcrete, piping & all for the water, soil heating this after the home & shop water system is in.

The longer term work of windmills & equipment for mini-grids seems about 2-years to having a town add them to their power base as a pilot project and the biodiesel from wastewater system is expected to be done within 3-4 years to production models with adequate financing.

Since adoption rates are key to scaling, please consider the high value of these integrations of needs into a self-sufficient home-farm-ranch on all basics of living, applying the long history of autonomous architecture and this attempt to tie them all together with what we have, recycled & OTS whenever possible, standard methods and materials.

To summarize, the dream is to remodel existing homes to being the place of refuge, shelter & food with the added need of biodiesel for IC-engines globally as the way to quickly reduce emissions.

Related proposals

Proposal on the biodiesel from algae grown from sewage effluent any scale: https://www.climatecolab.org:18081/web/guest/plans/-/plans/contestId/26/planId/1304273

References

These are a best way to learn how and why to apply Earthship principles based upon their experiences with off-grid living:

"A comprehensive seminar about the functioning of earthships, related systems, and the things you need to know about earthships."

2:32:09; http://www.youtube.com/watch?v=BHR5hyTBnSM

2:25:10; http://www.youtube.com/watch?v=LUUob15LOf8

"Easter Island Ancient Water Conservation Methods";

"This clip specifically focuses on the gardening practices of the inhabitants and how they where able to sustainable them selves. They show here gulleys, dams, pavements and what effectively looks to me as water retention, encouraging the water to soak in, conservation to stop runoff in heavy rains. Well they are that or "water gardens" if not. They also show how as well as cuttings down tree's they planted them too.";

3:38; http://www.youtube.com/watch?v=MXXyDh4YCBk

"Easter Islands Ancient Gardening Practices";

"This clip specifically focuses on the gardening practices of the inhabitants of the island from; slash and burn, lithic mulching, growing fruit in caves entrances for shade and building "manavai" stoned circle walls to protect plants from salt winds.";

12:32; http://www.youtube.com/watch?v=MWROy3lFwS8

"International climate exchange in the Potato Park, Peru";

"In April 2014, indigenous and ethnic minority farmers from Bhutan and China visited the Potato Park in Peru for a learning exchange on how to cope with climate change.

They learned from the many biocultural innovations of the five Potato Park communities, which collectively conserve 1,460 varieties of potato.";

15:36; http://www.youtube.com/watch?v=0rv6O8zaYio

"Inka Engineering Symposium 2: Inka Trails Near Machu Picchu";

"... Slope stabilization, drainage, retaining walls, stairways, viewing stations, controlled access, guardhouses and platforms, rest stops and water supplies for the traveler all add up to a spectacular success by the ancient Inka road builders.";

A terrace diagram is 24:30 from start, great symposium.

34:58; http://www.youtube.com/watch?v=tek3J-LMeKI